- Call Us for help!

- +91 9819742205

Manufacturer,Stockist and Exporter of Copper Finned Tube

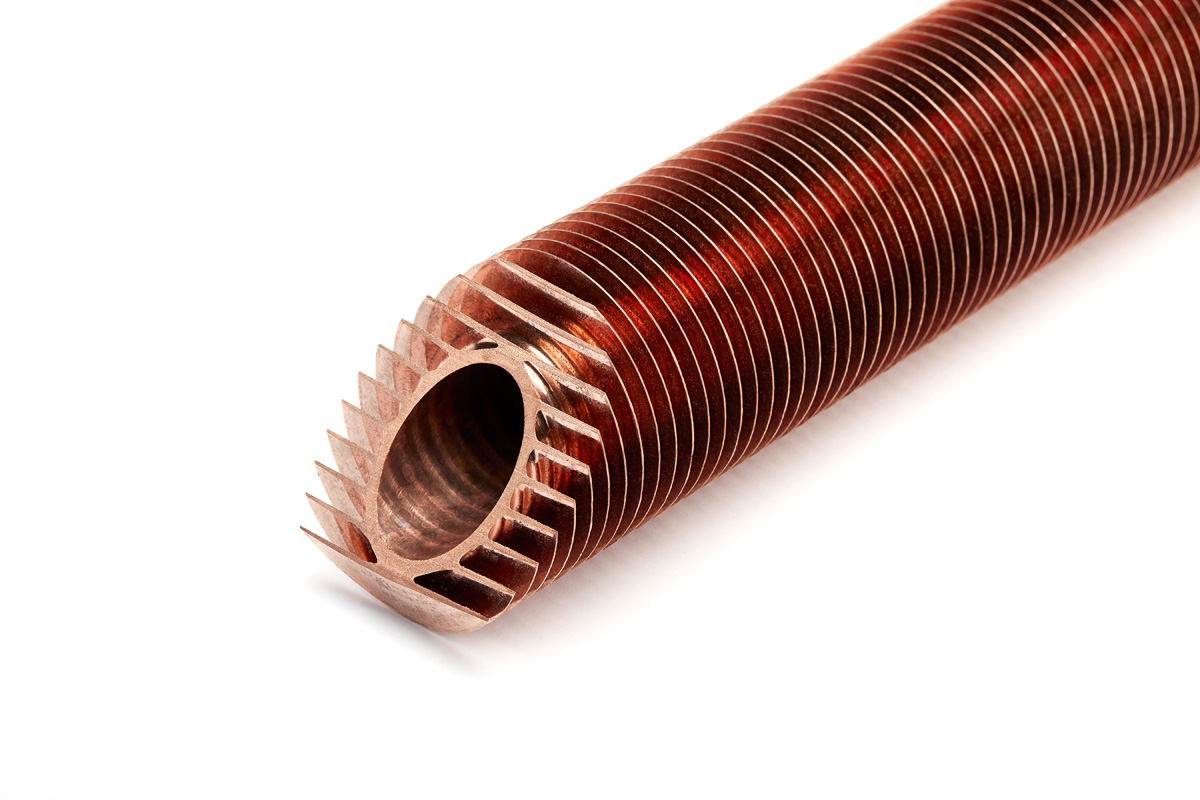

Copper Link International is a renowned manufacturer, stockist, and exporter of premium-quality copper finned tubes, which play a crucial role in heat transfer applications across various industries. These copper finned tubes are engineered to enhance the efficiency of heat exchangers, radiators, evaporators, and condensers by providing a larger surface area for heat dissipation. Due to the excellent thermal conductivity of copper, these finned tubes are ideal for applications that require fast heat transfer, such as HVAC systems, refrigeration, power plants, and chemical processing.

Copper Link International is a renowned Copper Finned Tube Manufacturer, Stockist, and Supplier, specializing in the production and distribution of high-quality copper finned tubes for a wide range of industrial applications. With a strong presence across multiple regions, including the United Arab Emirates, Saudi Arabia, Kuwait, Bahrain, Qatar, Oman, USA, Egypt, Algeria, Kenya, Mexico, Morocco, Nigeria, Tanzania, Spain, Germany, and France, Copper Link International ensures that businesses worldwide have access to premium copper finned tubes. These tubes are essential for heat exchange systems, providing superior thermal conductivity and efficient performance in industries such as HVAC, refrigeration, and power generation.

The copper finned tubes offered by Copper Link International are constructed using high-quality copper, known for its superior heat conduction properties. These tubes are fitted with copper fins that increase the surface area, which in turn improves the rate of heat exchange between the fluid inside the tube and the surrounding environment. This design ensures optimal performance in both heating and cooling applications. The copper construction also provides excellent resistance to corrosion, making these finned tubes suitable for both indoor and outdoor use in harsh environments.

Copper Link International’s copper finned tubes are available in a variety of sizes, designs, and configurations to meet the specific needs of their customers. The company manufactures both straight and spiral finned tubes, and can also customize the products based on particular requirements such as length, fin density, and tube diameter. Their manufacturing process adheres to international quality standards, ensuring high performance, durability, and reliability. With a focus on innovation and quality control, Copper Link International guarantees that their finned tubes perform at the highest levels, even under extreme conditions.

As a trusted Copper Finned Tube Stockist, Copper Link International offers a comprehensive inventory of copper finned tubes in various sizes, lengths, and specifications. These tubes are engineered to provide excellent heat dissipation, making them ideal for applications that require efficient heat transfer, such as in condensers, evaporators, and heat exchangers. Copper Link International's commitment to quality ensures that all copper finned tubes meet international standards and perform reliably under high temperatures and extreme conditions.

Specification Of Copper Finned Tube

| Tube Material | High-quality Copper (Cu) |

| Fin Material | Copper (Cu) |

| Tube Diameter | 10 mm to 38 mm (custom sizes available) |

| Fin Height | 3 mm to 10 mm (customizable) |

| Fin Pitch | 2.0 mm to 6.0 mm (depending on application) |

| Fin Type | Straight, Spiral, or Wavy Finned Tubes |

| Fin Thickness | 0.3 mm to 0.5 mm (depends on tube size) |

| Length of Tube | Custom lengths available (up to 10 meters or more) |

| Heat Transfer Area | Increased surface area for efficient heat exchange |

| Corrosion Resistance | Excellent corrosion resistance, especially in humid or marine environments |

| Working Temperature | Up to 200°C (depending on application) |

| Pressure Rating | Suitable for moderate to high-pressure systems |

| Application | HVAC systems, condensers, radiators, heat exchangers, refrigeration units, chemical plants |

| Finish | Bright, polished or as per customer requirements |

| Standards | Conforms to ASTM B111, ASTM B280, or other industry standards |

| Packaging | Individually packed or as per customer specifications |

As a trusted stockist and exporter, Copper Link International serves a global clientele, providing flexible solutions for industries ranging from oil and gas to automotive and marine applications. Their commitment to delivering high-quality copper finned tubes has made them a preferred supplier for large-scale projects and industrial applications worldwide. Copper Link International’s customer-centric approach ensures that every order is met with prompt delivery, competitive pricing, and outstanding after-sales support.

Copper Link International's reputation as a reliable Copper Finned Tube Supplier is built on a foundation of product excellence, competitive pricing, and timely deliveries. Whether servicing clients in the USA, Mexico, Morocco, Nigeria, Spain, or Germany, the company ensures that copper finned tubes are supplied to meet the specific needs of various industries. With a focus on customer satisfaction and consistent product quality, Copper Link International remains a preferred supplier of copper finned tubes for businesses around the globe, providing solutions that optimize heat transfer and improve system efficiency.

By maintaining a large inventory and leveraging a robust distribution network, Copper Link International ensures that its copper finned tubes are readily available to meet both small and large-scale demands. The company’s long-standing reputation for excellence in manufacturing and customer service makes it a reliable partner for industries seeking efficient heat exchange solutions.

Chemical Properties Of Copper Finned Tube

| Specification Parameter | Details |

|---|---|

| Tube Material | High-quality Copper (Cu) |

| Fin Material | Copper (Cu) |

| Tube Diameter | 10 mm to 38 mm (custom sizes available) |

| Fin Height | 3 mm to 10 mm (customizable) |

| Fin Pitch | 2.0 mm to 6.0 mm (depending on application) |

| Fin Type | Straight, Spiral, or Wavy Finned Tubes |

| Fin Thickness | 0.3 mm to 0.5 mm (depends on tube size) |

| Length of Tube | Custom lengths available (up to 10 meters or more) |

| Heat Transfer Area | Increased surface area for efficient heat exchange |

| Corrosion Resistance | Excellent corrosion resistance, especially in humid or marine environments |

| Working Temperature | Up to 200°C (depending on application) |

| Pressure Rating | Suitable for moderate to high-pressure systems |

| Application | HVAC systems, condensers, radiators, heat exchangers, refrigeration units, chemical plants |

| Finish | Bright, polished or as per customer requirements |

| Standards | Conforms to ASTM B111, ASTM B280, or other industry standards |

| Packaging | Individually packed or as per customer specifications |

Application:

- Electrical Industry

- HVAC Industry

- Plumbing Sanitary Ware Industry

- Automobiles Industry

- Constructions Industry

- Marine Engineering Industry

- Water & Gas Industry

- Earthing Systems Industry

- Electrical Engineering Industry

Our valuable Products

Etp copper bus bar, Oxygen Free bus bar,Tinned copper bus bar,Tinned copper flexible bus bar,Silver copper bus bar,Flexible copper bus bar,Copper Pipes,Copper Finned Tube,Nickel copper tube,Cupro Nickel Copper Finned Tube Copper admitory tube,Copper Fastener,Copper bolts,Copper washer,copper components,Copper forged Fastener ,Copper Fastener for electrical industry, Copper Tube & Pipes, Copper Coil,Brass Tube,Copper Nickel Tube,Copper Rod,

Countries we have exported our products to:

manufacturer stockist and exporter of Copper Finned Tubes in mumbai,manufacturer stockist and exporter of Copper Finned Tube in India,manufacturer stockist and exporter of Copper Finned Tube in United Arab Emirates,manufacturer stockist and exporter of Copper Finned Tube in Saudi Arabia,manufacturer stockist and exporter of Copper Finned Tube in Kuwait,manufacturer stockist and exporter of Copper Finned Tube in Bahrain Qatar,manufacturer stockist and exporter of Oman, manufacturer stockist and exporter of Copper Finned Tube in USA,,Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.

Cities we have supplied our products to

Bengaluru, Vung Tau, Nashik, Jaipur, Navi Mumbai, La Victoria, Al Jubail, Noida, Granada, Doha, Dammam, Ernakulam, Chandigarh, Santiago, Melbourne, Surat, Nagpur, Ranchi, Kanpur, Jakarta, Ahvaz, Indore, Jamshedpur, Muscat, Rajkot, Lahore, Chiyoda, Milan, Hong Kong, Riyadh, Houston, Busan, Calgary, Madrid, Visakhapatnam, Atyrau, Bhopal, Algiers, Colombo, Kolkata, Petaling Jaya, Dallas, London, Cairo, Thiruvananthapuram, Caracas, Howrah, Moscow, Port-of-Spain, Baroda, Mexico City, Gurgaon, Singapore, Aberdeen, Coimbatore, Kuala Lumpur, Perth, Ahmedabad, New York, New Delhi, Manama, Abu Dhabi, Montreal, Jeddah, Pune, Vadodara, Kuwait City, Chennai, Geoje-si, Tehran, Mumbai, Hanoi, Karachi, Pimpri-Chinchwad, Thane, Haryana, Ulsan, Seoul, Dubai, Ho Chi Minh City, Toronto, Hyderabad, Los Angeles, Faridabad, Lagos, Sydney, Courbevoie, Bangkok, Bogota, Rio de Janeiro, Ankara, Al Khobar, Ludhiana, Istanbul, Gimhae-si, Brisbane, Edmonton, Sharjah, Secunderabad, Gujratmanufacturer stockist and exporter of Copper Finned Tube in Bengaluru,manufacturer stockist and exporter of Copper Finned Tube in Chennai,manufacturer stockist and exporter of Copper Finned Tube in Hyderabad,manufacturer stockist and exporter of Copper Finned Tube in Gujarat,manufacturer stockist and exporter of Copper Finned Tube in Pune