- Call Us for help!

- +91 9819742205

Unlocking the Superiority of 63-37 Brass Pipes in Industrial Applications

Copper Link International is a leading manufacturer, stockist, and exporter of brass tubes. Renowned for their high-quality products and commitment to customer satisfaction, they have established a strong presence in the global market.

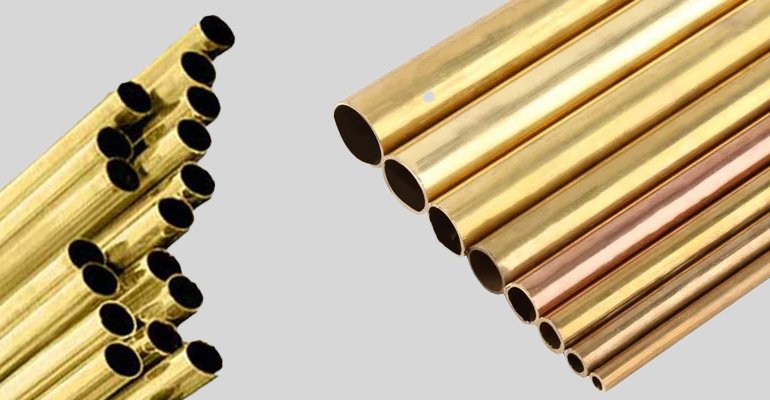

Brass tubes, manufactured by Copper Link International, are widely used in a variety of industries due to their exceptional properties. Brass, an alloy of copper and zinc, offers a unique combination of strength, corrosion resistance, and machinability. These tubes find extensive applications in plumbing, automotive, marine, and industrial sectors.

Copper Link International is a globally recognized manufacturer, stockist, and exporter of high-quality Brass Pipes 63-37, catering to industries across the United Arab Emirates, Saudi Arabia, Kuwait, Bahrain, Qatar, Oman, USA, Egypt, Algeria, Kenya, Mexico, Morocco, Nigeria, Tanzania, Spain, Germany, and France. Our Brass Pipes 63-37 are manufactured using premium-grade raw materials, ensuring strength, workability, and excellent corrosion resistance for both industrial and commercial applications.

The 63-37 Brass alloy (63% copper and 37% zinc) is widely used in plumbing, electrical systems, heat exchangers, and general engineering due to its excellent cold-working capabilities and decent corrosion resistance. At Copper Link International, we offer customized Brass Pipes 63-37 solutions in various sizes, wall thicknesses, and finishes to match customer-specific needs. All our products are manufactured to international standards such as ASTM B135 and EN standards to ensure consistent quality and performance.

As a trusted Brass Pipes 63-37 supplier and dealer, we maintain large inventory stock to support prompt deliveries globally. Our efficient logistics and supply chain make us a reliable partner for industries seeking high-performance non-ferrous metal solutions. Whether you need small batches or bulk orders, Copper Link International is equipped to serve your demands with unmatched service and competitive pricing.

Choosing Copper Link International means opting for durability, precision, and superior service. With years of experience in manufacturing and exporting non-ferrous metals, we stand out as a preferred Brass Pipes 63-37 stockist across various global markets.

Specification Of Brass Pipes

| Specification | Value |

|---|---|

| Material | Brass (typically 60-63% Copper, 37-40% Zinc) |

| Type | Seamless, Welded |

| Nominal Size | Varies widely (e.g., 1/8", 1/4", 1/2", 1", etc.) |

| Outside Diameter (OD) | Varies with nominal size (inches or millimeters) |

| Inside Diameter (ID) | Varies with nominal size and wall thickness (inches or millimeters) |

| Wall Thickness | Varies with application and size (inches or millimeters) |

| Alloy | C26000 (free-cutting brass), C36000 (red brass), C37700 (naval brass), etc. |

| Mechanical Properties | Yield Strength, Tensile Strength, Elongation (vary with alloy and temper) |

| Corrosion Resistance | Good resistance to many corrosive environments |

| Thermal Conductivity | Good thermal conductivity |

| Machinability | Excellent machinability |

As a leading stockist, Copper Link International maintains an extensive inventory of brass tubes, ensuring prompt delivery and minimizing project delays. Their efficient logistics and distribution network enable them to cater to the demands of both domestic and international markets. The company's commitment to customer service extends beyond product supply, offering technical support and expert advice to assist clients in selecting the most suitable tubes for their applications.

Application:

- Sugar Industry

- Plumbing

- Furniture

- Hand Pumps

- Ammunitions

- General Engineering

Key Features:

- Corrosion Resistance

- Superior Mechanical Properties

- Excellent Thermal Conductivity

- Electrical Conductivity

- Malleability and Formability

- Versatility in Applications

Corrosion Resistance

Our 63-37 brass pipes resist corrosion even in challenging environments, making them ideal for plumbing systems where exposure to water is constant.

Superior Mechanical Properties

With high tensile strength and hardness, our 63-37 brass pipes excel in applications where durability and mechanical performance are paramount, such as structural components in construction.

Excellent Thermal Conductivity

In electronics, the exceptional thermal conductivity of the 63-37 brass alloy ensures efficient heat dissipation, making it a preferred choice for heat sinks and electronic connectors.

Electrical Conductivity

The electrical conductivity of our 63-37 brass pipes makes them an ideal material for electrical connectors, ensuring reliable performance in various electrical engineering applications.

Malleability and Formability

The malleability and formability of the alloy allow for the creation of intricate designs, making our 63-37 brass pipes suitable for applications where complex shapes are required, such as customized architectural elements.

Versatility in Applications

Whether used in plumbing, construction, or electronics, the 63-37 brass pipes from [Your Company Name] showcase versatility, adapting seamlessly to diverse industrial applications, providing a robust and reliable solution in each context.

Frequently Asked Question

What is Brass 63-37 used for?

Brass 63-37 is commonly used in plumbing, electrical connectors, and industrial systems because of its good cold-workability and corrosion resistance.

Does Copper Link International offer custom sizes in Brass Pipes 63-37?

Yes, we provide customized Brass Pipes 63-37 in various lengths, thicknesses, and diameters based on client requirements.

Do you export Brass Pipes 63-37 to Europe and Africa?

Yes, we export Brass Pipes 63-37 to multiple countries including Germany, France, Spain, Egypt, Kenya, Nigeria, and more.

Which standards do your Brass Pipes 63-37 conform to?

Our Brass Pipes 63-37 comply with global standards such as ASTM B135 and EN norms, ensuring consistent quality and performance.

-

What sets 63-37 brass pipes apart from other alloys?The unique composition of 63% copper and 37% zinc in the 63-37 brass alloy provides a balanced mix of corrosion resistance, superior mechanical properties, and excellent thermal and electrical conductivity. This sets it apart as a versatile and high-performance material, ideal for a wide range of industrial applications.

-

Are 63-37 brass pipes suitable for outdoor applications given their corrosion resistance?Yes, absolutely. The corrosion resistance of 63-37 brass pipes makes them well-suited for outdoor applications. Whether used in plumbing exposed to varying weather conditions or in construction elements, these pipes demonstrate resilience against corrosion, ensuring long-term durability even in outdoor settings.

-

How does the quality assurance process at Copperlink International ensure the reliability of 63-37 brass pipes?At Copperlink International, we prioritize quality at every stage of production. Our rigorous testing processes include checks for composition, mechanical properties, and corrosion resistance. This comprehensive quality assurance ensures that our 63-37 brass pipes not only meet but exceed industry standards, providing our customers with products of the highest quality and reliability.